|

7/1/2006

It's been a very busy week down here. Lots of stuff going on at

work and at home. The Tour de France really snuck up on me... I had

planned to call the cable company just before it started and sign up

for digital (just for this month... I'm too cheap to pay for it all

year) so that I could get OLN and see the Tour. A friend of mine at

work taped it for me each day in years past, but this year he's got

a new girlfriend and isn't spending much time at home. Man, I

really got hooked on watching it every day... what an exciting race,

seeing it develop over three weeks as it does.

As I probably told you, I started working on the '68 Special last

week. I've got it down to the bare frame and cleaned up, next step

is to mix up some touchup paint. The particle size of that Masi

Champagne is very small, a lot of painters have had trouble

duplicating it. I went to the hobby shop and found some stuff there

that I think will work. It is made by Floquil and is for model

railroads.. supposedly it has more durability than other model

paints because the trains get handled more, and in addition the size

of the metal particles has been scaled down to look correct on a

small model. I got bottles of silver and gold, plus some black,

white, and primary colors to tint it with (looks like a 60-40 mix of

gold and silver with a tiny bit of green will do the trick but I

won't know for sure until I start mixing).

I was having a ball Sunday... Beth was up all night with the new

puppy so she stayed in bed quite late, giving me some peace and

quiet to putter around. I started going thru all my bicycle parts,

sorting and organizing (parts for the three bikes I'm

restoring/building were spread all over the house and the shop...

not any more), plus cleaning up stuff I've collected over the past

few years. Once I get all these parts in one place it should be a

lot neater around here. It was fun... I brought all the stuff to

one central location (out on the deck under the umbrella) and

enjoyed the breeze and the eager assistance of the puppy. Of course

all good things must come to an end... in the early afternoon, dark

clouds arrived. Two dark clouds actually, a sudden thunderstorm and

my wife finally waking up. I got everything inside in time, my

trips in an out punctuated by Beth's queries concerning how long all

that damned stuff is gonna be laying around.

Unfortunately, everything has to stay in the hallway until it's

sorted and boxed up. Right now my workspace in the shop is tight...

I've got bamboo stalks all over the place that need to be cut up and

sorted by diameter (for my brush handles) and the workbench is

occupied by a Thorens turntable I'm rebuilding (almost done). I

stripped it completely to relubricate it and replace the damping on

the suspension, as well as adding some cork damping on both sides of

the subplatter and the underside of the platen (common audiophile

mods, I'm told). That's mostly done, now I just need to build a new

plinth to set it into, since I prefer a flush-mounted turntable

rather than the boxy base it's in now. I also plan on doing some

work on the platter (there's this goop that looks like glazing

compound but it stays pliable for years... somebody found out that

it's great at stopping turntable platters from ringing so it's

become a popular mod. I put some on my old Gates and it works

great). Then just reinstall the Mayware tonearm... all that will be

finished in the next day or two and once that project is done I can

deal with the brush handles, and if all goes well the workbench can

take the bike stuff after that.

It'll be nice having all the bike materials out of the den. It's

crowded enough with all the books, albums, art supplies and computer

gear. My daughter hasn't been able to get her wheelchair in the

door for about a year which is not too big a deal, she has her own

computer now and there's really not much else in there she's

interested in. Lately tho, she's become a lot more curious about

music other than Queen which is about all she's been listening to

for the last year. I'm hoping when I get things cleared out we

can spend some time together listening to vinyl. Beth always

frowned on my preference for loud music ("You're not in college

anymore!") but with Sieren on my side she'll be outvoted, I guess

she'll just have to go shopping or something. To me, if music is

not at least within spittin' distance of live performance volume, it

ain't worth listening to (unless it's background music in which case

you're not really listening to it, are you?). Granted, some live

rock concerts are way too loud for me. But in most cases, it

doesn't matter if it's rock, pop, jazz, classical... there's a

certain minimum volume at which the music moves forward and becomes

the primary focus. Furthermore, nuances appear that are

inaudible at lower volume or at least not very well articulated,

things like fingers squeaking on acoustic guitar strings, clarinet

valves slapping, subtle harmonics in strings, snare drum rattles,

vocal textures, and so much more. Also, there's a sense of air

moving about the room when the music's louder. I don't mean a

blast of wind hurling you back in your seat like the Maxell guy,

just a subtle push from a distinct source, as when you are in the

presence of live music.

I can't wait to hear this Thorens once it's rebuilt. I retired it

when I got an old Gates Transcription turntable from the TV station

about ten years ago. I noticed right away that it was not as quiet

as the Thorens, but I kept it anyway because it was built like a

tank and had so much personality (if someone gave you an old

Deusenberg for free, you'd delight in driving it around for

quite a while wouldn't you,

even if it had no CD player and wasn't as good on gas as your

trusty Taurus?).

But it

finally got to me, I missed the Thorens and figured if I took

some time modifying it, it'd sound even better. A few days ago

I took it out of the box where it had been stored for the last

ten years and it didn’t seem to be in very bad shape… most of

the cosmetic blemishes were ones that I myself had inflicted in

various moves and thru frequent use. Taking it apart I could

see that the drive belt would need to be replaced… the rubber

seemed supple enough but I was pretty sure it was not as tight

as it should be. I ordered a new one the same evening off of

Ebay from a guy in England (twenty bucks). I guess I should

have looked around a bit, I later found a great site called

TurntableBasics.com that has a ton of nice turntable goodies for

much less (I think most of his belts were $10-12).

When I

removed the plinth and subchassis from the wooden base, I could

see that the foam inserts in the suspension springs would have

to be replaced… foam has a nasty habit of disintegrating over

the years, it just turns to powder. That’s why I avoid buying

speakers with foam surrounds, no matter how good they sound… in

five or ten years they aren’t going to sound the same and in

some cases you’ll remove the grilles and discover that the

surrounds have disappeared completely! This foam wasn’t that

far gone, but it was definitely too soft to serve the original

purpose. I was going to get some of that new upholstery foam,

which in my experience seems to have a longer lifespan… I don’t

know what type of plastic it is made of but you can tell it from

regular foam by the slightly waxy feel, like Nylon or Teflon.

But in the end I went with the old stuff since it is softer and

more compliant… it seemed important to try to match the

qualities of what Thorens originally selected. I cut some long

rectangles and trimmed them into octagonal tubes, then cut them

to length. The original inserts had shrunk a bit, plus the new

foam might have slightly different properties so I trimmed the

new ones to about three times the length of the originals with

the intention of cutting them down incrementally until I got the

performance I was looking for (in other words, a lively bounce

that would absorb vibration, but fast recovery once it was in

motion). Once they were cut to length, I burned a hole in the

center for the suspension bolts using a small pencil soldering

iron.

After all

the suspension spring parts were removed and cleaned up, I

proceeded to the subplatter (chassis). After cleaning out the

spindle well with Q-Tips and mineral spirits, I washed the whole

subplatter in soap and water to get the whole thing clean as

well as remove all traces of solvent from the well. I had a

small round brush used for cleaning aquarium tubing that would

have been perfect, but it had an exposed metal end and I was

afraid of scratching the bearing surface at the bottom of the

well so I went through another dozen Q-Tips instead. Once

everything was clean, I dried the exposed surfaces and dried the

well, first with more Q-tips, then with compressed air to flush

out any cotton fibers (be careful to hold the can of air

upright… some brands of canned air can spew a milky liquid when

tilted).

The next

step was to dampen the subplatter. I got a roll of adhesive

cork from Home Depot and traced out the pattern of all the holes

and other things I’d have to miss on the top and bottom surfaces

of the subplatter, then cut out the two pieces, being careful to

round off all the corners so they wouldn’t lift. I thought

about putting two layers on each side but after applying one

layer I held the subplatter by the spindle well and gave the

edge a tap and got a satisfying “thunk” instead of the metallic

ring it produced before so I figured the single layer was good

enough.

The next

step was purely cosmetic… the edge of the platter was extremely

oxidized, having the color and texture of lead, so I got out

some emery paper and set to work, going around the perimeter of

the platter with 180, 320, 400 and 600 grits, being careful to

work in long strokes and not spending too much time in one place

so as not to affect the balance (considering the small amount of

metal removed and the heavy weight of the platter there was

probably not much chance of that, but why take the risk?).

After the final grade of emery paper, I finished up on a buffing

wheel charged with emery, then Simichrome for the final polish.

The last

step before reassembly was to relubricate the spindle. I used

camelia oil, a very clean and lightweight oil that is used in

Japan to preserve samurai swords and woodworking tools. You can

leave the stuff on metal for years and it does not thicken or

dry out... sounded like just the thing for a turntable. Sure

enough, once I put the thing back together, I spun it by hand

and put my stethoscope on the subplatter and couldn't hear a

thing, what an improvement!

I have

been doing some reading about belt drive turntables and

supposedly the side to side wobble caused by belt tension as

well as the spindle-to-well tolerances do have an affect on the

amount of wow as well as the stability of imaging. In the past,

I have always heard that one should use a lightweight machine

oil for the spindle since it has the lowest friction but now I’m

hearing that heavier weight oils are better because they tend to

even out the inconsistencies of the belt tension as well as

evening out the cogging that some motors have. Sounds like

something interesting to experiment with in the future, but for

now I think I’ll stick with the lightweight oil since that is

what has worked (and been recommended by manufacturers) for

years.

Reassembly

was a breeze. When I first disassembled the springs, I counted

the turns it took to remove each nut and wrote the information

down. Years ago I had set spent some time setting up the

suspension for my Mayware arm, no sense having to find the same

balance point twice. So I tightened the nuts holding the

suspension back in their original positions and not having any

Loctite (and being too lazy to walk back up to the house to

borrow some nail polish from my daughter) I just locked them

down with a second set of jam nuts. As an afterthought I

realized that this was a better idea anyway since it would make

later adjustments easier.

I set the

assembly back in the wood base temporarily (it will eventually

be set flush into a routed dado in the top of my stereo cabinet)

and admired the work. The suspension was stiff because the foam

inserts were still at full length and won’t be trimmed until

tonearm installation and final setup, but the platter spun very

quietly and was nice and shiny. Not bad for a 30 year old

turntable.

Well, gotta go, Beth calls.

7/5

We just finished watching The World's Fastest Indian. If you

haven't seen it, rent it immediately, what a story. Not just an

amazing piece of history but very wonderfully told... Anthony

Hopkins did a great job, as did the rest of the crew. I was amazed,

even tho I knew much of the story already. Some great

accompanying materials on the DVD as well.

Was going to go down and work on my turntable tonight but I got

sidetracked by the movie. Yesterday I got the new plinth cut out

(just a large square of birch ply... doubles as the top of my stereo

cabinet) and edged it with 1/2" strips of alder. Today I removed

the clamps and checked the glue joints, but never got around to

planing the strips down to finish height and rounding the edges, or

cutting the hole... maybe tomorrow.

7/7

I made out like a bandit today... there are one or two models of old

audiophile and broadcast turntables that I've been keeping my eyes

open for and I keep getting beat out because they all go for way

more than I seem to be willing to pay. Yesterday, one of them was

set to close and it was at $175 and still hadn't made reserve... it

was an Ariston RD-40 that usually closes around $400 or more. I was

going to bid $250, pretty sure that wouldn't get it, but why not

take a shot? Well, we were very busy at work and I missed it, I got

to the computer a couple minutes after it closed. But surprisingly,

nobody else had tried to snipe... it was still at $175. So I wrote

the seller, told him I'd pay his reserve if it was within my price

range. He wrote back and said he'd lower his reserve to the high

bid, so I got it for $175 plus $25 shipping. Here's the kicker...

it's got a Sumiko tonearm, which usually goes for $200 by itself,

plus a $150 Grado Gold cartridge. So I'm pretty jazzed.

Funny thing, last night I was going to finish off the top for my

stereo cabinet... I had done the edging, I just needed to radius it

and do the finish sanding, then cut a hole for the Thorens. But I

had to work late, so by the time I got it sanded I was too tired to

set up the router and cut the hole. Good thing, or right now I'd be

starting over since the Ariston needs to sit on a shelf instead of

in a hole.

Beth's probably going to complain, but maybe it won't be so bad if

I just head out to the shop tomorrow and install the original

Thorens arm on the old turntable, put it back in its base and and

get it ready to sell. I should be able to get at least $75 or

so for it, given it's somewhat borderline cosmetics. Heck, I

might be able to get more if I can find someone who cares more about

performance than looks. Guess I'll sell the Gates too. Come

to think of it, I've still got my old AR out there in a box

somewhere, guess I could get rid of that one too.

7/9

I spent the day down in the shop finishing

off the Thorens... spruced up the old tonearm and installed it (I

put the old one back on since I'll probably sell it, no sense

installing the Mayware arm). Took a while to track down all the

parts and figure out how hook the arm lift back up. Thank goodness

I saved everything. Only thing missing is the arm rest which

is no big deal since the rest bar on the arm lift is very long and extends

past the arm's travel on both ends.

I brought it up to the house and set it up. I got the springs

adjusted, first the spring tension to get the platter level, then

gradually trimming the foam inserts until I the proper combination

of free bounce and fast recovery. Guess the guys at Thorens

knew what they were doing, by the time I got done the inserts were

down to almost exactly the same size as the originals. With a new Acutex cart

installed, I balanced and adjusted the arm, then popped on an old Chick Corea album on and sat back. Man, it sounded great

for an old turntable, even with the original arm... not as crisp and alive as

the Mayware arm, but still very clean.

Then the nightmare began... I got about halfway thru one

side and the right channel started buzzing. Switched sources on the

preamp and the buzz was still there (so it's not the turntable), turned the volume up and down

and the buzz stayed the same volume (so its not the preamp)... must be the power amp.

Turned the preamp off, sure enough the buzz was still there. Damn.

I pulled the power amp out and hooked up the right channel speaker.

I could get the buzz to go away by thumping on the top, but the

slightest jar and it would come back. I guess I could pull the lid

and wiggle some stuff to see if I can see where it's coming from but

right now I'm just too pissed off and depressed.

Maybe I should just look for another amp... these GFA-535's seem to

be going for about $150 on eBay, I'm sure this one would cost me at

least that much to get fixed.

Man, seems like I have the worst luck sometimes...

10PM

I guess the problem may have been heat related, after being off for

an hour it started working again. It's kind of strange tho, we

listened to music for the rest of the evening at a reasonable volume

and the buzz never came back even tho the amp must have reached the

same operating temperature as before. I'm keeping my fingers crossed.

7/13

Well, the Ariston arrived. Beth's asleep so I haven't had to

answer any questions yet. I wonder... if I just don't say

anything, how long will it take her to notice that there's a new piece of gear

in the house?

Anyway, a cursory look reveals some damage (the seller didn't remove

the platter or lock down the suspension). The motor works fine so

there's cause for optimism... if I can straighten the bent rod that

holds the suspension springs (looks like a standard bolt to me,

might even be able to replace it) everything will be OK. I'll know

more after I get it apart.

Will write more later...

7/14

Well, my sweet little Ariston RD-40 turntable that I've been waiting

for arrived yesterday. I was a little worried when I saw the box,

it seemed a little small... the seller (or shipper) certainly didn't

double-box it. Once I got it unwrapped, I could see that there was

a major screw up... he did not lock down the suspension or remove

the platter, which means that the thing was bouncing around in

transit. Sure enough, two of the suspension posts were bent and the

whole turntable was crooked.

Trouble is, I have been playing around with bicycles a hell of a lot

longer than I've been playing with Aristons and when I saw that the

whole thing was put together with allen bolts something inside me

just snapped. Some sort of primal instinct took over and I ran to

the bike tool box and returned with allen wrenches... no harm in

just taking apart ONE of the suspension posts, might be nice to know

if there's a part in there that I can just bend straight, or if not

maybe it's something easy to replace. I got the sucker apart and

sure enough the only thing that was bent was a 5x.08 metric bolt

that ran up thru the center of the post. Not gonna find a metric

bolt that long at the hardware store but no matter, I can bend both

bent bolts straight with no problem.

Well, the outside of this suspension post housing sure looks

rough... as long as I've got it apart, maybe I should shine it up a

little, where's my Simichrome? Another trip back to the toolbox.

Wow, that's shiny. Hmmm... the rest of this thing's pretty dirty

too, guess I should take the platter off and see how bad the inside

looks. But first we need to take the tonearm off, need a small

socket... maybe I should just bring the whole damned toolbox. OK,

that was easy... lay the tonearm aside, lift off the platter. Man

there's no damping on the platter, I bet this thing rings like hell,

I'll have to do something about that. Geez, look at the oil down in

that well, sure is dark and thick, maybe I should clean it out with

mineral spirits and put some fresh oil in there...

So it came to pass that a half hour after I first slit open the box,

this audiophile turntable is now sitting in front of me in pieces

like an old Masi... my daughter's calling me, reminding me that I

promised we'd go out to dinner and I'm thinking that after we get

back I'll just pick up all these pieces and haul them down to the

shop and do the job right, take apart every single piece and get

everything all shiny and new and ready for the bike concours, er...

the stereo cabinet.

7/15

The turntable has always been my favorite component... I guess

because it is primarily mechanical and I've always been fascinated

by mechanical objects that move in interesting ways. Or that

allow designers to attack a specific problem from different creative

directions, each allowing the finished product to function well and

be pleasing to the eye. Much the same as bikes.

And just like bikes, there are many turntables and tonearms I'd love

to own, but I can't for the life of me think of where I'd put them.

Actually, I COULD mount three tonarms on one of those Micro Seiki

DDX-1000's, but no way I could spare the room to set up a bunch of

turntables.

Still, after working on my Thorens and the Ariston, I've found

myself

thinking that I could make a regular thing of buying and fixing up and

reselling turntables to bankroll other projects (or to allow me to continually

trade up until I end up with something really exotic).

The Ariston's almost done. Would have had it together tonight but

for a couple of setbacks. First, I decided I should make a tonearm

plate for the Mayware while the thing's apart and I can use the

old plate as a pattern. Second... crap... today I started cleaning

up the two aluminum base castings with a little soap and water and

the paint came off... it just sloughed off in these huge stretchy

sheets. Those jerks painted it with waterbase acrylic paint and no

primer! I couldn't believe it. I got out the alcohol just to check

and sure enough it dissolves the paint... definitely acrylic.

Good thing I've got a rattlecan of flat black in the shop. I

stripped and sprayed one piece first to make sure it was a good

texture match to the original, then stripped the second piece a few

hours ago and just finished shooting the second paint coat... so I

should be able to assemble it tomorrow. Jeez, what kind of idiots

would paint metal with unprimed acrylic paint?

Beth still hasn't noticed the new turntable... of course how would

she, I've been carrying it around in unrecognizable pieces. She did

ask me yesterday not to wash my bike parts in the kitchen sink, that

was when it dawned on me that she probably just thinks the turntable

is a bicycle.

7/16

Well, after a couple of days of far more involved work than I had

planned (among other things, repainting the entire subchassis), I

got the Ariston up and running. Tonearm still needs some tweaks (at

least everything works) but it sounds great, even as is.

7/17

As a project it bore remarkable similarity to rehabing a bike...

lots of mechanicals in need of cleaning and Simichroming and

tweaking, and an unexpected paint job that presented itself at the

last minute.

Anyway, took it for a test drive yesterday. Tonearm still

needs a lot of work, but that's the fun part since involves

actually listening to music...

The Ariston sits proudly on top of the stereo rack, all shiny and

sci-fi looking... I keep wondering when Beth is gonna notice it.

7/18

Well, I'm all fixed for tonearm board material for a while... I went to the

local

glass company and got a 1/2" slab of plexiglass , about 8" x 2',

then stopped at the cultured marble place and got some scraps of

3/8" and 3/4" Corian. Well, it's not Corian, its something they

make on site but I'm sure its close to the same stuff. The marble

guy was nice, gave me some nice large scraps for nothing, but the

glass guy charged me list for what was obviously a scrap ($17). Anyway, I've got some

stuff to play with.

Considering that the machining operations are fairly routine and

I've got way more tools than I used to have (3HP plunge router and

solid router table, drill press, etc.) these things should not be too time

consuming to fabricate. I'm now wondering if there's even some

money to be made selling arm boards for discontinued turntables.

Right now, I'm just thinking about this Ariston... I think I'll

start with the plexiglass since it is easier to machine and it's the

best thickness, I don't want to go with anything thinner than what's

on there (the marble is .375", but it'll be even thinner by the time

I sand down the rough back side, and the original board is .4").

The 3/4" marble is probably too thick for the screws. Plus the

plexiglass is lighter and since that arm pod is outboard of the

suspension towers, it'll probably have less effect on the balance.

Did I tell you I'm gonna have to make two arm boards? Not just for

the Mayware, but the Sumiko board has to be remade... I noticed that

the cart screws were all the way at the back of the headshell slots

so I checked the overhang and it was way off, about 1/4 too long."

So I checked the arm specs at VinylEngine.com and sure enough, the

arm was mounted about 6mm or so too close to the spindle. So I'll

probably cut three boards, one for each arm and one blank which I'll

put on eBay and see what it brings.

7/19

Well, I may have jumped too soon getting the arm board materials

locally... I just found a few nice sources on the web for all sorts

of plastic sheet, all different varieties, and some of it in black

so I won't need to paint it. Guess I'll hold off on the

arm boards until I get some of this stuff. Might as well go

ahead and get some clear acrylic or polycarbonate so that I can make

a dust cover as well. The acrylic's cheaper but the

polycarbonate's a lot more resistant to scratches so maybe it'd be a

good idea to

spend the extra few bucks, assuming I can find the right glue.

There's a plexiglass glue available locally that wicks into the

joint and bonds the pieces so that there's almost no trace of a

joint... don't know if the same stuff works on polycarbonate or not,

but a little bit of web research should give me the answer.

7/20

Today's Audiophile Tip, Number 42.

You know that tube of 25 year old damping fluid that has been

sitting in the little box where you keep your cartridge hardware

and the collection of little complimentary screwdrivers they

give you with each new cartridge? If you have any thoughts

about putting that stuff in your tonearm for it's intended

purpose, don't. It is no longer damping fluid, it is now

primordial goop, suited only for spawning the next generation of

silicon-based micro-organisms that are someday destined to take

over the planet.

Well, come to think of it, it does have one other use... you

know that tonearm lift that always lowered too fast? Maybe it

always lowered too fast, or maybe it worked great when you first

got it but the fluid inside dried up or leaked out and now it

lowers your cartridge like the express elevator in the Sears

Tower? Well, just take the thing apart, get out your spatula

and trowel some of that vintage damping fluid on the piston of

your tonearm lift and your troubles will be over. That sucker

will now descend as gently as the feather in the opening credits

of Forrest Gump.

Tomorrow's tip:

Make cryo'ed cables in your own freezer, we show you how.

7/25

Looks like I'm

stalled out for a while until my stuff arrives.

Thank goodness

for the net. After a few minutes of research I found out that

the polycarbonate is not going to be worth the hassle.

Apparently, the stuff is porous so if you don't want a chalky glue

joint resulting from trapped moisture, you have to dry the stuff in

an oven before you glue it. No thanks. So I ordered some

1/4" acrylic instead, plus some 1/2" black plastic for the arm

boards.

I also ordered

some connectors from Markertek to make some cables. Not a bad

deal, they have some very robust looking all metal connectors with

gold plated ends and guts for just $2.60 each (Canare F-10's).

Not sure what kind of wire I'm going to use yet... FIM makes some

monocrystal solid wire that is only $1.29 a foot after cryo-treatment.

Then there's some 5/9 continuous-cast copper stranded wire from

Vampire (also cryo-treated) that is more expensive, but I may go for

it because I like the suppleness of stranded wire, especially for

interconnects (they seem to get moved around more than speaker

wire).

Let's see, what else is new? Oh yeah, I ordered a new belt for

the Ariston which came yesterday and boy did it need it. The

thing comes up to speed much faster, almost as fast as a direct

drive. Plus there's enough torque now to clean records with

the Parastat without turning the platter by hand, though I usually

do that anyway to avoid putting strain on the motor.

Also in the package from Turntable Basics were a couple of syringes

of damping fluid. Some thin stuff for the Sumiko and Mayware

arms, plus some thicker stuff for the pistons inside the arm lifts.

Man, my days of doing without are over. The net is amazing...

20 years ago finding a drive belt even for a common turntable like

my AR was a major deal that involved ordering a catalog, writing a

check, and (lots of) waiting. And if you wanted something more

esoteric like damping fluid, forget it. Now the stuff is at

your fingertips, just a few clicks away. Hmm... what else can

I buy? Maybe some nice headshell wires or a cool digital

stylus force gauge.

7/29

Well, it's

Friday and the plastic has not arrived so I guess I won't get to

work on the turntable this weekend as I'd hoped. It's just as

well, it will give me a chance to think and form a plan of attack

because there are a few tweaks I want to do to the rest of the

turntable while I'm making the new arm boards.

The problem is noise. There is a very low level vibration

from the motor that I'm hearing when the stylus is in a silent

groove. It sounds like a ground hum but it disappears when I

lift the arm off the record so I guess it has to be motor noise

making its way into the platter somehow. It is quiet enough so

as to be inaudible when music is playing, but there's no sense

living with it if there's a chance of making it better.

Every turntable

I've ever owned was audible when you turned it up more than

halfway. Yeah, I know how little that means, halfway on a

volume pot could be anything from 2% to 80% of full power.

Anyway, what I'm saying is that the turntable always had a noise

floor that was higher than most other components. Most of the

time, it was a ground hum, and I can't tell you how many hours

I've spent chasing grounds to get the quietest possible

performance from my turntables. But once you got the ground

taken care of as best you could, then there was almost always

some motor noise. Which a lot of people would mistake for a

residual ground problem since an AC motor is obviously going to

produce vibrations and harmonics around 60Hz.

In my old Thorens

and AR, the motors were reasonably well isolated but there was

still some noise that made it thru the chassis and up into the

tonearm. But the Ariston's very quiet. When the arm's on the

rest, there's almost dead silence, which is a new one on me, at

least with the amp turned up this far. Problem is, you can turn

it down to say, 1/4 (9 o'clock) and place the stylus in a silent

groove at the end of a record and you can definitely hear motor

noise.

So how do I

attack this?

First off, is there possibly something wrong with the motor?

Before I do anything else I guess I should lubricate the shaft since

the motor is the only thing I didn't mess with when I was rebuilding

it. Stupid, I know, but typical of my tendency to mess with

things mechanical and shy away from things electrical.

Assuming that doesn't fix the problem, then I need to look at the

two routes that vibration can take to reach the platter. The

first is through the belt. Not much I can do about that

really. However, I can eliminate it as the culprit by

disconnecting the belt and setting the stylus down on a record to

see if the sound is still there. If it is, that means it is

coming through the lower chassis, through the springs, then into the

upper chassis and platter. I really hope this is the case

since there appear to be several ways to isolate the various

components more effectively than they are now. The motor is

already isolated from the lower chassis by a cork pad, but

it may have compressed over the years and be in need of replacement.

Also, the allen head bolt that holds the motor housing in place provides a

direct path for vibration so it might be a good idea to get an

o-ring to fit between the bolt head and the chassis. Next

stop on the path is the suspension spring housings. Noise

would have to pass from the lower chassis to the lower housings,

thru the springs, into the upper housings and into the upper

chassis. And both ends of the springs are insulated with thick

rubber grommets. Doesn't seem likely that motor vibration

would survive that trip but you never know. Right now, both

the top and bottom

halves of the housings are bolted into concave channels on the upper and lower

chassis. It couldn't hurt to do the same treatment here as is

presently on the motor, namely cork padding in the channels.

Adding

o-rings under the bolt heads couldn't hurt either.

8/4

The plastic has arrived but I've been too busy to work on the arm

boards or the dust cover. I did get a chance to do a bit of

diagnostic work on the turntable however. The hum is definitely

making its way to the platter via the belt and I've not been able to

find a way to reduce or eliminate it. Going back to the older (and

looser) belt didn't help, neither did experiments with alternate

belts (of thread and monofilament). It finally dawned on me that

this much hum might not be normal and after searching some of the

forums and reading about folks with similar problems I am finally

over my denial, ready to accept the fact that this thing is going to

need a new motor.

A few more web searches made my mood a bit sunnier. Apparently the

motor that is in this Ariston (24 pole synchronous, 51mm dia, 3mm

shaft) is quite common in mid-to-high-end turntables and

replacements are still available. Premotec and Airpax (links below)

seem to be the most common. I guess I will probably order the first

one since it's listed as 110v and that's what's in the Ariston.

Premotec Motor

Airpax Motor

I ran across an interesting site that has DC motor upgrades (link

below), starting at about $350 and going (way) up from there.

Supposedly they are quieter, more stable, and longer lasting.

Still, on my budget it is hard to justify a motor that costs twice

(at least) what I spent for the whole turntable, tonearm and

cartridge. But given all the remarkable testamonials on the site it

might be worth considering in the future, should I win the lottery.

Oh hell, if I win the lottery I'll give the Ariston away and get an

E.A.R. magnetic drive turntable... what's $13K to a

mega-millionaire?

Origin

Live DC Motor

8/14

I was really getting sick of waiting this past week... everyday I

would come home to find no package. Ah, but today was different.

Yes, dear friends, I bought another turntable, and today it finally

got here. Like the Ariston RD-40, the Technics SP-15 was one of

those turntables I lusted after years ago when I was just out of

college and could barely afford to feed myself. I've been tracking

the prices on eBay and this one was cheap enough for me to grab and

certainly cheap enough for me to resell at a profit. The plan is to

live with both turntables for a while and decide which one I want to

keep. The Ariston's definitely nicer looking, or at least more

distinctive, and as a belt drive it probably has the potential to be

quieter overall (or will be when I replace the motor). But the

Technics is good looking in its own way and has an aura of power and

professionalism and sturdiness about it... you hit the start button

and it comes up to full speed in 1/4 of a revolution, and

it stops even faster (it has both a magnetic and mechanical brake).

Also, I play guitar occasionally (well, not so much these days) and

after three decades of belt drives I think I might enjoy having a

turntable with one full tone of speed adjustment so I can tune the

damned thing to the guitar instead of the other way around. On the

other hand, the SP-15 goes against my love of simplicity (and my

tendency to want to tweak). Logic chips, PC boards, the interior of

this thing looks more like a computer than a turntable (at least it

does in the maintenance manual, I haven't had it apart yet). All my

other turntables were like my bicycles, I could strip them down

myself... and this is something that becomes more important now that

most of these old tables aren't in production anymore.

You know, the last thing I need is another project, but I'd really

love to build my own turntable. I have been coming across quite a

few 'tweaker's' audio sites where these guys who were fond of

modifying their turntables finally took the plunge and tried

building them from scratch (tonearms too). Some people had critical

parts custom machined, others built everything themselves. Still

others found creative uses for parts from other fields (including

bicycle components). One guy built a turntable spindle with a

high-performance aftermarket intake valve and valve sleeve for a

Harley Davidson motorcycle. Another guy built a damped unipivot

tonearm with a golf ball suspended in a tiny vat of molasses (I'm

serious). Wonder what he does about ants? Very cool (and weird)

stuff... and inspiring as well, makes me want to build one of my

own.

Ah, but before I get into scratch-building, the first order of

business is getting the stuff I've already got on hand running well, then sell off what I don't want (or can't afford) to

keep. After examining the Technics I can see that like the Ariston

it needs some work. The on/off switch will often make double contact

when switched (press it once when off and it will turn on and

quickly off again... press it when running and it will do the

opposite). Watching the switch I see that after it is pressed it

rises very slowly, as if it is damped. The plan at present is to

live with it for a bit, perhaps it is stiff from a long period of

disuse. If it doesn't loosen up, I guess we shall have to take it

apart and clean it.

When the turntable was running, I could hear a scraping noise.

Looking thru the finger lift holes and listening closely, it

appeared to be coming from the plastic cover for the mechanical

brake. Apparently the flat top has warped upward a bit...

understandable since plastic often migrates over time, either

relieving stresses leftover from the injection molding process or

reacting to being screwed down to an immovable chassis. Anyway, I

can see the rub mark on the cover, perhaps I can scrape that portion

of the surface down a bit, or heat it up and massage it down so that

it's flat again. In the meantime, I'm just going to leave the cover

off.

Next problem is the tonearm. The AT-1010 seems to be a very nice

arm but it's got Audio Technica's cheap pressed headshell rather

than the one I suspect originally came with this arm. Rats, I just

saw one on eBay last week, I should have snatched it. Oh well.

Also, the arm pillar seems to be jammed in the base. Loosening the

lock screw doesn't do a thing, I sure hope that pillar isn't rusted

in there. No, here's the problem... looking at the underside of the

turntable it appears the hole was drilled a bit off-center. The

pillar is wedged up against the MDF plinth and can't move. I'll

have to enlarge that hole, both to allow me to adjust VTA and to

have access to the locking ring for the signal cables that is hidden

up there.

In fact, perhaps I could enhance the value (and versatility) of

this table by just routing a large circular half inch dado in the

plinth to accept interchangeable arm boards. Four inch diameter,

same as the Ariston... that will save me some setup time, I can just

fabricate a half dozen identical discs for both tables. I probably

should add some holes to the ones that will go on this turntable tho,

the two holes that Ariston used do not seem adequate.

Only other bugaboo that appeared in tonight's setup and listening

session was the arm lift lock... like the one on the Sumiko arm,

this one is broken Unlike the Sumiko, the piece is missing so

repair is not going to be as easy. First off, I need to track down

some photos, either on the web or maybe my buddy Alan will

photograph his for me. Once I know what the original looks like I

can see about making a faithful repair. If that's not possible,

I'll just have to improvise.

Other than the above problems which I see as minor and easily

fixable, the initial listening was very favorable. The turntable is

rock solid... the sound overall was nice and punchy, the bass was

extremely tight and the noise floor was way down, even quieter than

the Thorens was just after its tuneup. I was reluctant to accept

Technics' stated -78dB S/N spec, it seemed hard to believe when the

platter is connected to (hell, it's part of) the motor, but I guess

they weren't kidding.

Just as an aside rant, let me say that I often wonder about the

psychological aspects of sound perception. In this case, my feelings

about the turntable's performance are, perhaps not coincidentally,

quite similar to my impressions of its physical appearance in

comparison with the previous unit... heavy, solid, etc. Perhaps this

is part of what makes me skeptical of so many reviews I read online

and in magazines. In the absence of true double-blind testing, our

perceptions are easily colored by factors that many reviewers are

aware of but dismiss all too readily. Take the hypothetical example

of a reviewer who opens a carton containing a new set of cables that

are satisfyingly heavy, fabulously well crafted, and frightfully

expensive... I firmly believe that there will always be an

unconscious tendency to assume that those cables are going to sound

great, before they even get hooked up. I don't think it is possible

for any reviewer to be completely objective, even if he is aware of

just how powerful the mind's biases may be, and even if he makes

every honest effort to compensate for them.

If total objectivity were truly the ultimate goal, then I believe

that the methods of equipment review would be quite different than

they are now. Reviewers would spend a lot more time seeking

repeatable results with scientifically controlled testing instead of

just jotting down vague impressions using adjectives that few

members of the general public understand.

I am not suggesting that we return to the days when equipment tests

were mostly charts and tables and the verdicts of test equipment

were given precedence over the ears of a music lover. For years

after the transistor amp became popular in the 60's, musicians

desperately tried

to tell us that they sucked. They kept using their tube amps, while the

public trusted the lower noise and distortion figures published by

the audio magazines... and nearly killed the tube amp in the process.

What I am suggesting is that critical listening tests can be

practically meaningless unless the reviewer does NOT know what

combination of gear he's listening to. If he does, then there is no

way that psychology (bias, expectation, interaction, confirmation,

etc.) can fail to have an effect on the results. In the above

example, instead of the reviewer opening the carton containing the

new cables submitted for review, an assistant would do so. Then he

would flip a coin. Depending on the results of the toss, he would or

would not install the cables in the review system. The reviewer

would then arrive and would be advised that the room had been

prepared for the morning's listening session... this information

would not come from the assistant, but from a third party. This is

critical... the assistant must not be able to indicate through voice

inflection or body language what had been done to the system. You

would be surprised the subtle cues an astute observer can detect (in

fact, even animals are good at it... ever seen a horse do long

division?). Perhaps the third party would be so generous as to

inform the reviewer that he may or may not be listening to a new set

of cables, or he might say nothing and just retire to the kitchen to

prepare the reviewer a cup of his favorite tea. The reviewer would

then begin to listen. Sounds dangerous, doesn't it? If the reviewer

hears pronounced changes when the system is in fact unchanged, he's

in trouble. Sorry friends, the world is cruel... who said equipment

reviewing had to be safe?

Ask any scientist... double-blind testing is what it is all about.

Repeatable results using valid scientific testing methods would go a

long way toward convincing the many skeptics (among whom I

occasionally count myself) that thousand dollar a foot interconnect

or speaker cables can make a huge difference in the sound of a

system.

I'm not suggesting that all cables sound alike, far from it. I only

have a problem with the degree of improvement that manufacturers

attribute to them in an effort to justify their tremendous cost. My

guard immediately goes up when a manufacturer zeroes in on one meter

of cable in a highly visible location yet does not seem anxious to

address the hundreds of feet of circuit board traces inside the

equipment that remain out of sight and out of mind. If

cryogenically-treated monocrystal wire is so important to good

sound, why aren't component manufacturers doing away with PC boards

and returning to point-to-point wiring using this superior material?

Surely several hundred feet of circuitry inside a piece of gear is a

more sensible target for improvement than the meter or so between

components.

Well, back to the Technics...

For all you folks who buy an old SP-15 that's been laying around a

while, a word of advice. Don't get scared if you attempt to remove

the platter and it doesn't budge. The spindle has a Morse taper

(like a drill press or lathe) and that platter will probably be

stuck to the spindle. If it's been on there a while, it may be

stuck TIGHT. Here's what you need to do... this is gonna sound

scary, but trust me. The spindle will lift about one fourth of an

inch before stopping (this is to allow you some clearance to oil it

I guess, the illustration in the manual shows it being lifted when

oil is being applied). Do NOT force the platter and spindle any

higher if it seems obvious that the platter's not going to come off

easily. Anybody who has replaced a shear pin on a lawnmower engine

without having a flywheel puller can probably guess what's coming

next. Get a few strips of plastic or wood (popsicle sticks work

well) and place them under the perimeter of the platter to hold it

(and the spindle) up. Then GENTLY tap the spindle with an implement

of choice (not your 28 oz framing hammer, maybe try a small tack

hammer or that old Empire tonearm you've got stashed in the bottom

of a drawer) and the spindle will drop down. Now you can lift off

the platter. When you examine it, you may find some dried oil

residue was the 'glue' that was sticking it together, and you will

probably want to clean everything with a dab of mineral spirits on a

small piece of chamois before you reassemble it (but carefully...

no mineral spirits trickling down the spindle, please). And don't

be surprised if it locks again, that's what tapered shafts do. On a

lathe or drill press they are supposed to release with a firm tap

from the side... but on a turntable any sort of force from the side

seems ill-advised. I'd stick to the soft-blow-from-above method

since the spindle already has some play in that direction and

dropping the short one fourth of an inch after it releases doesn't

seem likely to damage anything, assuming you're careful of course.

I guess that's all there is to report with the new turntable. I

can't wait to listen to some more music tonight, I think I might

move the Acutex cartridge over from the Ariston so that I can

eliminate one more variable in the overall setup. My daughter is

anxious to hear the rest of the Renaissance at Carnegie Hall album

we started last night and I'd like to revisit an old Ronnie Laws

album that I haven't listened to in fifteen years.

Oh, one more thing. The turntable came with a set of the old Audio

Technica isolation feet (you remember these... one of the first sets

of feet to hit the market, maybe the first). These guys have a wide

aluminum covered plastic base, with a studded rubber mat sole. On

top of the bases are smaller cylindrical plastic adjusters that

screw up and down (and wobble side to side a bit also, one would

assume to absorb vibration and to provide some self-leveling). The

plastic cylinder is in turn topped by a felt layer to further absorb

vibration and protect the underside of the plinth. I've seen tons

of these things but never owned a set so naturally I spent some time

playing with them. I placed the stylus on the blank area of a

Telarc Test Disc, then thumped and knocked my audio cabinet at

several points on its side and under its shelves to see how much of

the sound made it to the speakers. Considering that these puppies

aren't hand-lathed by Middle-Earth dwarves from solid cryo-treated

brass and don't cost $675 each, I gotta say they work pretty well.

One thing I did notice tho, and I'm pretty sure this is not my

imagination, these things work better upside down. That is, with

the small felt cylinder underneath and the knobby rubber mat on

top. Hard to believe that the folks at Audio Technica would have

been dumb enough to invert these things from their "proper"

orientation, but it would appear so. Who knows, maybe the shop

foreman was holding the blueprints upside down, eh?

What's that you say, I did not test this scientifically? You are

absolutely correct, I will try to do that in the next few days. Double blind... the

tester will not be present and the listener(s) will not know what

they are listening to. Here's how it goes... I will leave the room

after instructing my wife to thump on the cabinet and asking both

her and my daughter to listen closely to the resulting sound coming

thru the speakers. Then they will leave the room and I will flip

the feet when they can't see what I'm doing, then ask them back in

to repeat the experiment, having told Beth to thump the cabinet

exactly as she did before (naturally Beth does the thumping because

as the biased tester I might thump more or less loudly in accordance

with my expected results). After I write down their impressions of

the sound, they leave the room and I swap the feet again... or maybe

I will leave them in the same position this time, just to throw them

off. The point is, only I will have a record of whether the feet

were up or down, while the two folks who are thumping and listening

will neither know the orientation of the feet, nor in fact will they

even know it is the feet that are being tested. After several

tests, I can compare their impressions (louder? softer?) with the

recorded orientation of the feet during each trial and see if there

is a pattern. See folks, THAT is a reliable test, not some lone

loonie (me) getting an idea that these things sound better upside

down and then testing his hypothesis with a self-regulated process

guaranteed to produce predictable results.

I'll let you know what happens (assuming the wife and kid consent to

cooperate).

January 2007

Well, I bit the bullet

and bought a new power amp. Found a good deal on an Adcom

GFA-545. So far it appears to sound about the same as the 535

in terms of soundstage and overall flavor. Only difference I

can hear is perhaps some improved transient detail. That and

it takes up more space.

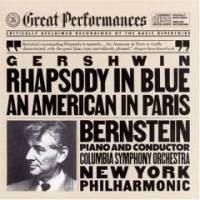

Hey, you know how you're still attached to certain pieces of music

that you heard way back when? My favorite version of Bach's

Brandenburg Concertos is probably nothing to write home about but

it's the one I grew up with so I always go back to it.

Unfortunately, it has been out of print for years... a small CD

reissue was released by some French label several years ago but it

is out of print also (plus it was mono... apparently the stereo

master has gone missing). Anyway, this recording may not be

the type of performance that's in fashion these days, but if you

find this album in a record shop, on eBay or at a flea market, do

yourself a favor and buy it.

|